Technicalities of Electrical Issues

Behind the Curtain: Testing Today’s Porsche Electrical Systems

Cracking the Code: Testing Today’s Porsche Electrical Systems

Once upon a time, diagnosing a car meant listening for knocks, checking spark plugs, or following a trail of oil. Those days are long gone—especially if you're working on a modern Porsche. Today, Porsche vehicles are less mechanical beasts and more intelligent machines on wheels, with electrical systems that rival those of modern aircraft in complexity.

As an automotive enthusiast or technician, it’s not just about turning wrenches anymore. It’s about understanding networks, high-voltage architecture, and the software backbone that ties everything together. Here’s a look behind the curtain at how Porsche engineers test and validate these complex electrical systems—and what it means for the future of automotive diagnostics.

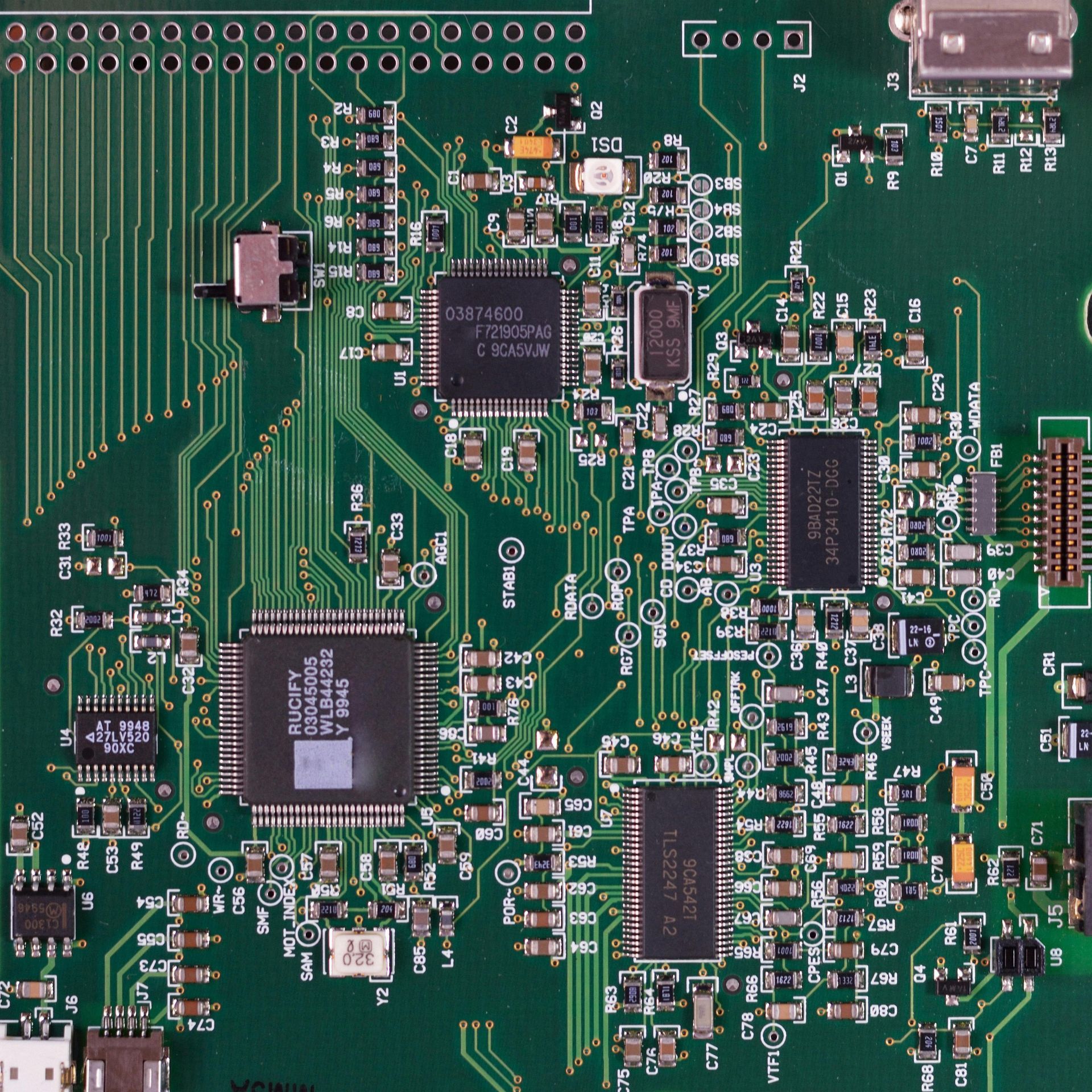

The Brain of the Beast: Software Meets Silicon

Modern Porsche models can have over 100 Electronic Control Units (ECUs) working in sync—from managing high-voltage battery packs to regulating air suspension, to even knowing when you’re approaching your garage. All of this is coordinated through sophisticated software governed by strict automotive standards like ISO 26262 for functional safety and Automotive SPICE for software development quality.

To keep things running smoothly, Porsche integrates automated test environments into their software development cycle. These systems simulate real-world scenarios and continuously verify that every line of code is reliable before it ever touches a production vehicle.

HiL Testing: Simulating Reality Before Reality Hits

One of the most advanced methods Porsche uses is Hardware-in-the-Loop (HiL) testing. This setup places real ECUs into a simulated environment where they behave as if they’re in a fully assembled car, but without needing the physical vehicle.

Why is this important? Because it lets engineers test critical systems—like electric motor control or battery charging—under hundreds of scenarios, from hard cornering on a frozen road to sudden high-speed charging on a hot summer day. All of this happens safely, in a lab, long before any car hits the production line.

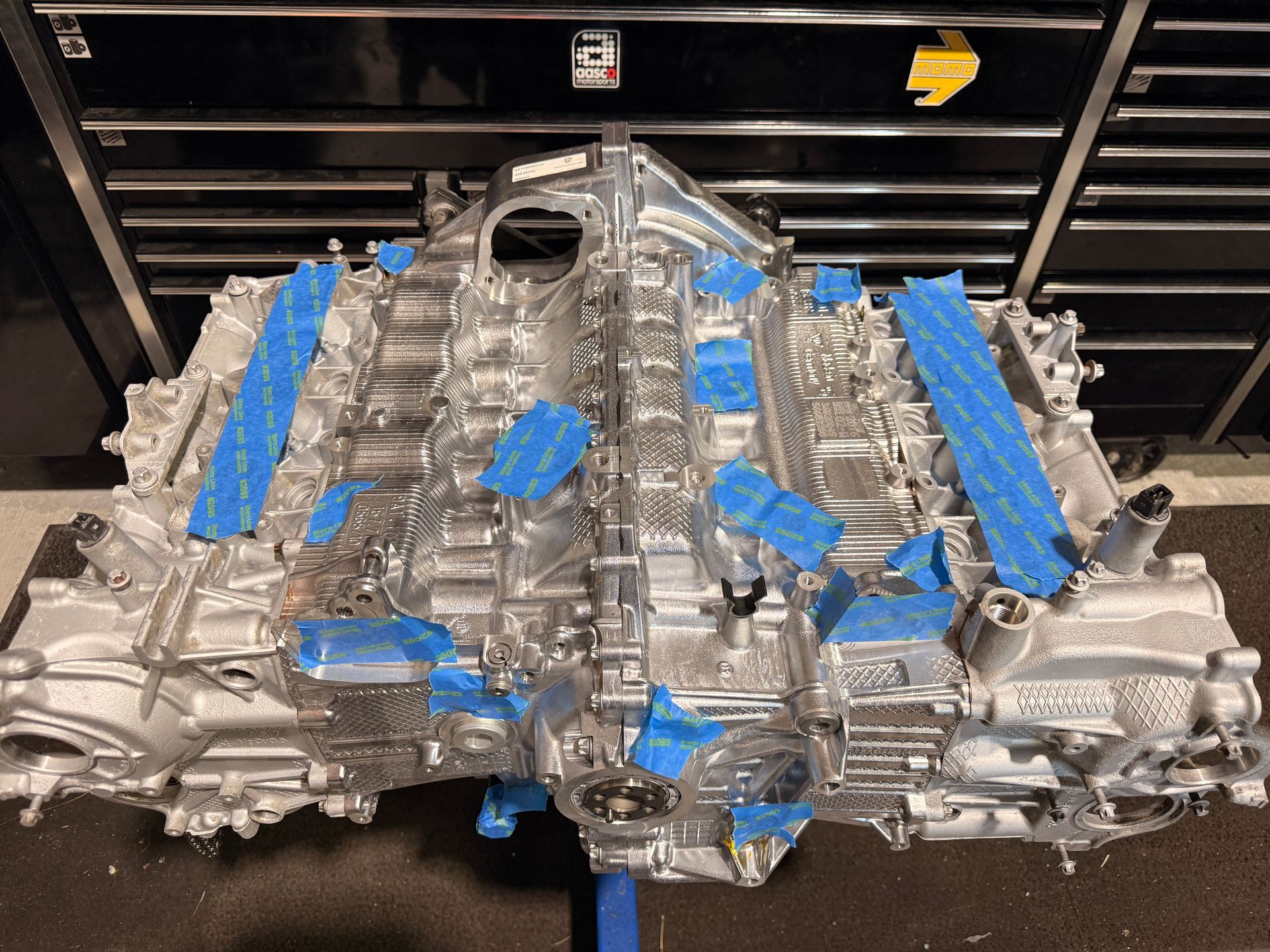

Battery Testing: The Heart of an Electric Porsche

As Porsche transitions further into the EV era (think Taycan and the upcoming electric Macan and Cayenne), testing the high-voltage battery systems becomes even more essential.

Porsche engineers put these battery packs through thermal stress testing, real-world endurance tests, and high-voltage simulations. It’s not just about range and charging time—it’s also about making sure these systems don’t degrade too quickly and can handle extreme conditions from -30°C to +50°C.

They even simulate long-term use to explore second-life applications for used EV batteries, such as stationary energy storage.

CAN Bus & Ethernet: The Nervous System

Under the skin of a Porsche, the CAN (Controller Area Network) and increasingly, automotive Ethernet, act as the nervous system. These networks allow ECUs to talk to one another in real time. Whether it’s adaptive cruise control sharing data with the braking system or the entertainment unit syncing with your mobile device, it’s all connected.

Testing these systems means diving deep into signal integrity, error detection, timing issues, and network load balancing. Engineers use powerful tools like oscilloscopes, network sniffers, and diagnostic software to detect even the tiniest communication glitch.

Environmental Testing: From Snowstorms to Heatwaves

While lab simulations are powerful, there’s still no substitute for the real world. Porsche prototypes undergo grueling field tests across the globe—from icy Scandinavian landscapes to sweltering deserts in the American Southwest.

Every ECU, wiring harness, and connector is pushed to the limit. Vibration testing, water intrusion, corrosion exposure, and shock resistance are all part of the package. If something fails in the wild, it goes back to the lab for analysis and redesign.

Why It All Matters

You might wonder why all this complexity and testing is necessary. The answer is simple: Porsche’s reputation is built on performance and reliability. Whether you're rocketing from 0–60 in a Taycan Turbo S or crawling through traffic in a hybrid Cayenne, everything—from throttle response to brake feel to charging speed—must be perfect.

In the world of Porsche, electrical systems aren’t just support mechanisms—they’re part of the driving experience.

Final Thoughts

Testing modern Porsche electrical systems isn’t just about finding faults—it’s about pushing boundaries. The team at Velocity Motorwerks understands the complexity of these systems and undergoes hours of training to stay ahead of the curve. The integration of real-time simulation, automated validation, and world-class engineering ensures that every vehicle that rolls off the line is not only fast and luxurious but incredibly smart and safe.

Whether you’re a technician, a Porsche fan, or just someone curious about where the auto industry is headed, one thing’s clear: the future of automotive engineering is electric, connected, and deeply complex—and Porsche is already there.